scratch test tribology|Tribological Behavior of New Martensitic Stainless Steels Using : export The scratch test: Atlas of failure modes. In World Tribology Congress: Abstracts of papers (pp. 495). Institution of Mechanical Engineers. WEB16 de set. de 1995 · 315 followers. Add Jarlan Barrera's info to your website! No team. Nationality. COL. 16 Sep 1995. 28 yrs. Height. 171 cm. Preferred foot. Left. Position. M. .

{plog:ftitle_list}

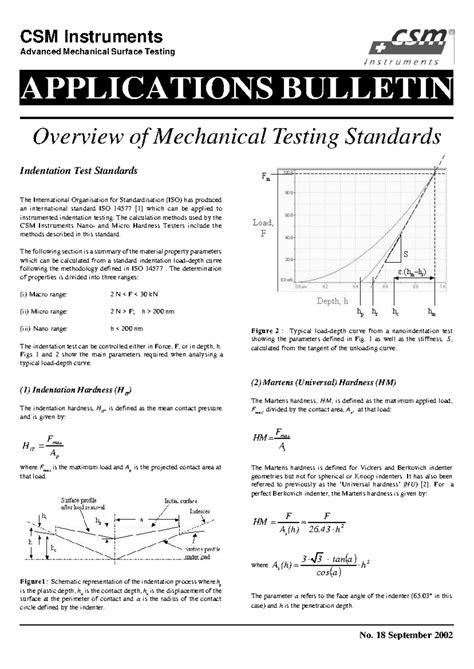

O nobreak é um dispositivo de segurança que protege os equipamentos contra variações de tensão e outros problemas de energia que podem danificar os componentes .

A three-dimensional (3D) scratch model is proposed to investigate the effects of yield strength of both coatings and substrates.The scratch test allows obtaining critical loads, scratch friction coefficients, .

A three-dimensional (3D) scratch model is proposed to investigate the effects of yield strength of both coatings and substrates.Tribology testing with the Alemnis Standard Assembly (ASA) is possible in several different configurations, depending on the application. For example, the scratch testing option can be .The scratch test: Atlas of failure modes. In World Tribology Congress: Abstracts of papers (pp. 495). Institution of Mechanical Engineers.

In this paper the load regimes in which the main adhesion-related failure modes (spallation and buckling) occur as a function of coating thickness will be presented for .Scratch testing is commonly used for investigating the integrity of thin films and coatings by measuring the scratch resistance, viscoelastic recovery and onset of cracking. It can also be used to simulate the action of a cutting tool (e.g., drill . The scratch test method can be used to investigate a two-body-abrasion on a lab-scale and is defined as an ideal single tribological contact. Depending on the material .3D Scratch, Indentation and Tribology Tester. 03. What is a 3D Scratch Tester? Combination of high accuracy scratch tester and optical profilometer. Comprehensive analysis of deformation .

We have performed multiple scratch tests for a variety of polymer samples: poly-propylene, polytetrafluoroethylene and a polyester. In each of the materials studied, the .2015, Tribology International. Citation Excerpt : Fig. 3 illustrates the damage evolution of the DLC film during scratch testing under a progressively applied normal load from 0 to 80 N. The rupture or flaking of the film surface resulted in a discrete acoustic emission with high amplitude produced by the violent release of stored elastic .

500 0 0 2 4 Thickness 6 8 (pm) Fig. 5 Scanning electron micrographs of scratch test failure modes in TiN coatings: (a) buckling and (b) wedge spallation; and alumina oxide scales on MA9.56: (c) buckling and (d) wedge spallation .Scratch tests were conducted on copper with a conical indenter. 3D morphologies of the scratches were obtained by a 3D Surface Profilometer, and the influence of normal force on the scratch groove was studied. The results show that width and depth of the scratches increase linearly with the increase in the applied normal force. When the normal force is high, the . Our telegram channel for Abaqus and Q&A: https://t.me/abaqus_asistOur Telegram channel for FFS, Structure Integrity and the analysis of fixed equipment:https.

A three-dimensional (3D) scratch model is proposed to investigate the effects of yield strength of both coatings and substrates. With the help of combined Coulomb and plastic friction, the obtained results comprehensively interpret the experimental phenomena in most metals that with the growth of hardness after heat treatment the scratch friction coefficient (SFC) .Tribology And Mechanical Tester With Integrated Profilometer 05 Open Platform U channel design, high Z access provides large working . The scratch test requires applying a load on the sample that needs to be tested with a spherical or custom tip. During the process of applying the

TY - CHAP. T1 - The scratch test. T2 - World Tribology Congress 1997. AU - Meneve, J. AU - Vercammen, K. AU - Andersson, Peter. AU - Varjus, Simo This method uses a progressive load scratch test and digital image analysis software to more precisely quantify where the onset of scratch visibility occurs. . The basis for interpreting polymer tribology. Tribol. Int., 31 (1–3) (1998), pp. 121-126. View PDF View article View in Scopus Google Scholar [15] The scratch test has been used to assess thin coating adhesion for some time now. In this test a diamond indenter is drawn across the coated surface under an increasing load (either stepwise or continuous) until at some load, termed the critical load, L c a well-defined failure event occurs; if this failure event represents coating detachment then the critical load .

Tribology testing

Tribology is the science and engineering of understanding friction, lubrication and wear phenomena for interacting surfaces in relative motion.It is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. [1] The fundamental objects of study in tribology are tribosystems, which are .Bruker's mechanical testers and tribometers provide the most comprehensive and versatile means of investigating tribology—friction, wear, load, hardness, and lubrication. Measuring friction, wear, and material mechanical properties is a way for engineers to understand how materials, coatings, and lubricants will stand up to the rigors of .

Rubber Impact Resiliency Tester service

Its large working area and most comprehensive test conditions represent a highly customizable instrument with a full list of environmental chambers and options. Main Features. . Our bench-top tribometer for tribology, wear, and scratch tests. With a patented integrated 3D profilometer and real-time force control, the MFT-2000 is easy to use. . The scratch test has been used to assess the adhesion of thin hard coatings for some time now and is a useful tool for coating development or quality assurance. However, the test is influenced by a number of intrinsic and extrinsic factors which are not adhesion-related and the results of the test are usually regarded as only semi-quantitative.

The test was conducted with reference to ASTM G171-03 (Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus), modified for thin coatings. The scratch hardness of a material can be determined by producing a scratch on the sample surface with a sharp, hard (diamond) tool with known tip geometry, under a constant, load. The failure modes observed in the scratch test depend on many factors and are most easily characterised in terms of the hardness of both substrate and coating (Fig. 1).In the case of a typical Rockwell ‘C’ diamond indenter (120° cone with 200. μm hemispherical tip), for soft coatings and soft substrates the test is dominated by plastic deformation and groove . 1. Introduction. The scratch test is a routinely used technique to measure the adhesive strength of coatings at the interface, but obtained results depend on many extrinsic and intrinsic parameters [].Scratch hardness, abrasion resistance and wear of bulk materials can also be evaluated using scratch test [2, 3].The mechanical properties extracted during scratch . Samples were investigated and analyzed under macro scratch adhesion test and wear tribology test. Scratch width measured for both samples reveals SiC sintered in air atmosphere have the least track width of about 27% and 15% less than SiC sintered in Ar for 50 N and 100 N scratch loads, respectively. Also, scratch depth penetrated into SiC .

Micro-scratch experiments were performed on copper with a spherical indenter, and the effect of sample tilt on the scratch response of copper under different constant normal loads was studied. The results showed that the experimentally measured nominal friction coefficient was linearly related to the sample tilt angle, with their slope being unaffected by the normal load. The . By comparing the obtained results with those of similar materials or coatings, the relative scratch resistance of the sample can be determined. Scratch Tests Parameters. Researchers can monitor different scratch parameters during the test, such as applied load, scratch length, and scratch speed, to further understand the material’s scratch .Scratch Tester is used to calculate the adhesive force on the coating-substrate materials. . Force tester is a three-point bending test apparatus used to determine flexural stress, flexural strain and flexural modulus of a beam. . The subject tribology deals with the technology of lubrication, friction control, and wear prevention of . This paper focuses on the tribological characterization of new martensitic stainless steels by two different tribological methods (scratch and dry wear tests) and their comparison to the .

Scratch Testing; Tribology; DMA; SCRATCH TESTING. The basic principle of the scratch test is that an indenter of known geometry (commonly a spherical diamond) is dragged across a surface with either constant or progressive loading. In the case of coatings, a progressive load is usually used for generating an increasing stress until failure .The synchronization of scratch data and 3D imaging ( Patent US 10,024,776 B2) is a unique and novel tool to study surface deformation and failures. Piezo actuator for precise down motion during scratch test. The best friction force sensitivity on the market owing to normal and tangential force sensors located in the head.

Semantic Scholar extracted view of "Failure mode maps in the thin film scratch adhesion test" by S. Bull. Skip to search form Skip to main content . , title={Failure mode maps in the thin film scratch adhesion test}, author={Steve J. Bull}, journal={Tribology International}, year={1997}, volume={30}, pages={491-498}, url={https://api .

Pin in Disc tribometers are probably most known and extensively used devices in tribology. The tribometer consists of a stationary pin and a rotating disc. Pin is loaded by a dead weight or actively controlled systems. . Scratch test instrument is a simple for evaluating adherence characterization and scratch resistance for thin coatings and .The tribometer offers breakthrough technology in tribology equipment— with ultra low resolution and negligible thermal drift force sensors, highest speeds, widest environmental control range, . medical devices, etc. The quantitative coating adhesion scratch test is a simple, practical test that has been around for a long time. But reliable .

Tribology behavior on scratch tests: Effects of yield strength

The numerical study of the scratch test on glassy polymers needs a well adapted mechanical behaviour law both viscoelastic and viscoplastic. To test different models, an algorithm which allows to assembly in series two models has been developped. In our cas, it is used to associate a viscoelastic model with viscoplastic one. The simulations carried out lead to some .

Tribological Behavior of New Martensitic Stainless Steels Using

Resumo de “Amor Eterno: Os Maiores Romances da História”: O amor é um tema universal que tem sido explorado na literatura, cinema e música ao longo da história. Um dos romances mais famosos de todos os tempos é Romeu e Julieta, de William Shakespeare, que conta a história de dois jovens apaixonados que pertencem a famílias .

scratch test tribology|Tribological Behavior of New Martensitic Stainless Steels Using